Request FREE Quote

You can customize and get a machine on your own parameters.

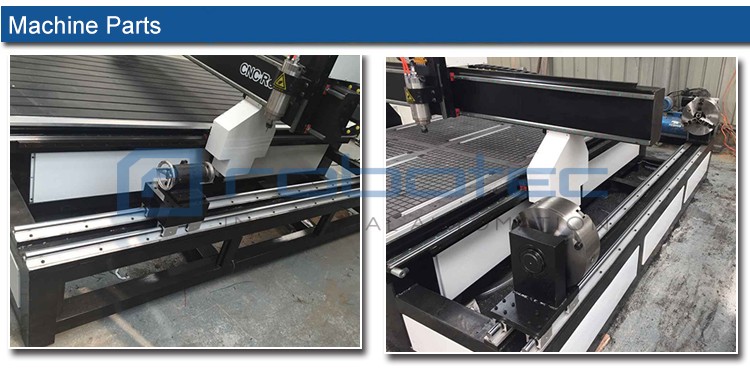

| Model | RTM-1325RH wood cnc router |

| Working area (X*Y*Z) | 1300*2500*200mm |

| X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

| X,Y,Z Repositioning Accuracy | ±0.03mm |

| Table Surface | Vacuum and T-slot Table |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Power Consumption | (Without Spindle) 2.5kw~3Kw |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 3KW |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Stepper System |

| Working Voltage | AC380V/50/60Hz,3PH (Option: 220V) |

| Command Language | G Code |

| Operating System | DSP System(Options: Ncstudio/Mach3 PC Software) |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| Collet | ER20 |

| X,Y Resolution | <0.01mm |

| Software Compatibility | Type3/UcancameV9 Software, (Option: Artcam Software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

PS:All the working area and specifications can be customized according to your requests.

>>Features

1300*2500mm working area.

with rotary device for cylinder object.

Vacuum working table. Mechanical fixing small processing materials.

3kw Italy HSD air cooling spindl, It’s big strength and higher efficiency.

Dust collection system, it can keep a clean, less-dust working surrounding which is helpful to your healthy; also, it can reduce the surface dust of linear guide, ball screw and gear transmission, reducing the maintaining cost.

>>Applications

Wood furnitur industry: Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on.

Advertising industry: Advertising indentification, sign making, acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

Die industry: A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand, plastic sheeting, PVC pipe, wooden planjs and other non-metallic mold.

Relief sculpture and 3D engraving.

Cylindrical object.

![B(R[)}ZOR%AR542{WCS1]9.jpg](/uploads/allimg/181121/11203B529-4.jpg)

1. Service before order: our salesman will try to know more about your demands , including the max working size, main processing materials and the thickness , so we will offer you suit machine.

2.Service during production : we will send the production the machine pictures for customer in time , customer can know more the detailed machine parts.

3.Service before shipping : the machine parts will be installed and tested by our professional.

technician, send the test video according to customer’s processing materials for customer confirmations.

4.Service after shipping : we will check when the machine arrive your sea port or the approximate arrival date, so that the customer can know the arrival date and to prepare to pick the machine up

5.Service of training : the English manual and operating video will be sent to customers with the machine together, it will help customer how to operate the machine , it there is any question about the operation , we will have the professional technician to help them how to operate by online ,until the customer can use it freely.

6.Service of warranty : we guarantee the machine for Two Years, some machine parts ( quality problems ) can be free charge to replace it within warranty.